Let’s talk briefly about how we’re going to heat our house. Currently, we have electric baseboard heat. It’s actually fairly efficient — it converts about 95% of the electricity into heat. But we’re investing in something even more efficient — and, key to a small house like ours, it allows us to use all the wall space that’s currently taken up with heaters.

So what is this wonder of which I speak? Officially known as an air-source heat pump, you may have heard it called a “mini-split.” Chances are you’ve seen one as the A/C-only units are popular in restaurants. This is the Sanyo unit we’ll be using (comes with a handy-dandy remote)…

If you want a really good explanation of why it’s more energy efficient, you should read this. So our new heat pump was installed a few days ago…

With some aesthetic changes and the elimination of the dark purple paint, eventually that mildly unattractive white rectangle above the window will disappear from view. We hope.

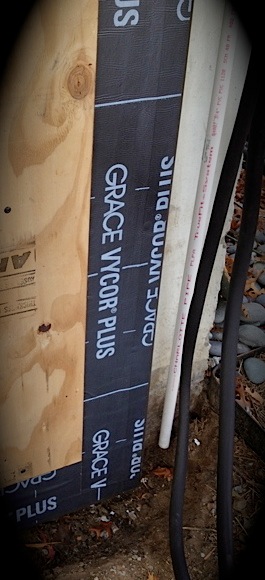

There are two refrigerant lines, the electric cable and a small PVC drain line for any condensation that forms in the summer or in winter when the unit is in defrost mode. The connections run down inside the double wall…

The hoses exit outside where they travel inside a piece of PVC over to the compressor…

I’ll clean up that expanding foam and seal a piece of metal flashing over the hole to maintain our water and air infiltration integrity, and to keep out 4- and 6-legged vermin.

An outside unit (the compressor) takes heat out of the air and pumps it into refrigerant which is circulated through pipes to the indoor unit (in summer the process is reversed)…

The compressor is relatively small considering it provides 32,000 BTUs of heat — and 34,000 BTUs of cooling. It can support up to four connections. We’ll be using just two: a 9,000 BTU unit downstairs and a 24,000 BTU unit in the upstairs living area. Each is connected to the compressor with two copper refrigerant lines wrapped in black foam insulation, and a 3-wire cable carrying electricity to the fans in the inside unit. The wire also carries signals from the inside units back to the compressor telling it whether to send heat or cooling, and how much to send. The compressor has a variable-speed DC motor which can run faster or slower as needed to suit demand. This makes it much more efficient than a simple on/off compressor.

Now that our electrician has made all the wiring connections, RAM Mechanical (our HVAC installer extraordinaire) will return to double-check the refrigerant connections for leaks. Before they left, they filled the hoses with nitrogen under pressure. If the pressure has dropped over the last week they’ll know something is amiss. Hopefully this is just a precaution and later this week we’ll have heat! In a month or two we’ll compare our past electric bills to the current ones and know just what we’re saving with the new system.